Coffee Processing

DDV CULINARY

Processing of coffee is the method converting the raw fruit of the coffee plant (cherry) into the commodity green coffee. The cherry has the fruit or pulp removed leaving the seed or bean which is then dried. While all green coffee is processed the method that is used varies and can have a significant effect on the flavor of roasted and brewed coffee. PickingCoffee berries are most commonly picked by hand by labourers who receive payment by the basketful. As of 2003, payment per basket is between US$2.00 to $10 with the overwhelming majority of the labourers receiving payment at the lower end. An experienced coffee picker can collect up to 6-7 baskets a day. Depending on the grower, coffee pickers are sometimes specifically instructed to not pick green coffee berries since the seeds in the berries are not fully formed or mature. This discernment typically only occurs with growers who harvest for higher end/specialty coffee where the pickers are paid better for their labour. Mixes of green and red berries, or just green berries, are used to produce cheaper mass consumer coffee beans, which are characterized by a displeasingly bitter/astringent flavour and a sharp odour. Red berries, with their higher aromatic oil and lower organic acid content, are more fragrant, smooth, and mellow. As such coffee picking is one of the most important stages in coffee production, and is the chief determinant for the quality of the end product. Processes

Coffee processing aquapulp

Wet Process

Sorting coffee in water

Coffee drying in the sun. Dolka Plantation Costa Rica

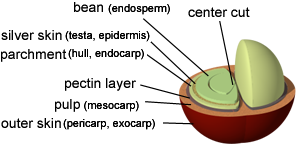

Most of the world's green coffee has gone through some sort of wet processing including most of the premium coffee. After the Green coffee is picked the coffee is sorted by immersion in water. Bad or unripe fruit will float and the good ripe fruit will sink. The skin of the cherry and some of the pulp is removed by pressing the fruit by machine in water through a screen. The bean will still have a significant amount of the pulp clinging to it that needs to be removed. In the ferment and wash method of wet processing the remainder of the pulp is removed by breaking down the cellulose by fermenting the beans with microbes for several days and then washing them with large amounts of water. Fermentation can be done with extra water or in "Dry Fermentation" in the fruits own juices only. In machine-assisted wet processing fermentation is not used to separate the bean from the remainder of the pulp rather it is scrubbed off by a machine. After the pulp has been removed what is left is the bean surrounded by two additional layers, the silver skin and the parchment. The beans must be dried to a water content of about 10% before they are stable. Coffee beans can be dried in the sun or by machine but in most cases it is dried in the sun to 12-13% moisture and brought down to 10% by machine. Drying entirely by machine is normally only done where space is at a premium or the humidity is too high for the beans to dry before mildewing. When dried in the sun coffee is most often spread out in rows on large patios where it needs to be raked every six hours to promote even drying and prevent the growth of mildew. Some coffee is dried on large raised tables where the coffee is turned by hand. Drying coffee this way has the advantage of allowing air to circulate better around the beans promoting more even drying but increases cost and labor significantly. The parchment is removed from the bean and what remains is green coffee. Dry ProcessDry process, also know as unwashed or natural coffee, is the oldest method of processing coffee. The entire cherry after harvest is placed in the sun to dry on tables or in thin layers on patios. It will take between ten days and two weeks for the cherries to completely dry. The cherries need to be raked regularly to prevent mildew while they dry. Once dry the skin, pulp and parchment are removed from the bean. While coffee was once all dry processed it is now limited to regions where water or infrastructure for machinery is scarce. The supply of dry processed coffee is very limited with coffee from the Harrar region of Ethiopia and some areas of Yemen and Brazil being the primary sources. Semi Dry ProcessSemi dry is a hybrid process in very limited use in Brazil and Sumatara/Sulawesi. The cherry is passed through a screen to remove the skin and some of the pulp like in the wet process but result is dried in the sun and not fermented or scrubbed. Additional Steps

Sorting GradingOnce the coffee is dried to green coffee it is sorted by hand or machine to remove debris and bad or misshapen beans. The coffee is also often sorted by size and placed into one of several grades. PolishingSome coffee beans are polished to remove the silver skin. This is done to improve the green coffee beans appearance and eliminate a byproduct of roasting called chaff. It decried by some to be detrimental to the taste by raising the temperature of the bean through friction which changes the chemical makeup of the bean. Storage

green coffee stored in bags

Green coffee is fairly stable if it is stored correctly. It must be placed in containers that can breathe — often, some type of fiber sack — and kept dry and clean. AgingAll coffee, when it was introduced in Europe, came from the port of Mocha in what is now modern day Yemen. To import the beans to Europe the coffee was on boats for a long sea voyage around the Horn of Africa. This long journey and the exposure to the sea air changed the coffee's flavor. Later, coffee spread to India and Indonesia but still required a long sea voyage. Once the Suez Canal was opened the travel time to Europe was greatly reduced and coffee whose flavor had not changed due to a long sea voyage began arriving. To some degree, this fresher coffee was rejected because Europeans had developed a taste for the changes that were brought on by the long sea voyage. To meet this desire, some coffee was aged in large open-sided warehouses at port for six or more months in an attempt to simulate the effects of a long sea voyage before it was shipped to Europe. Although it is still widely debated, certain types of green coffee are believed to improve with age; especially those that are valued for their low acidity, such as coffees from Indonesia or India. Several of these coffee producers sell coffee beans that have been aged for as long as 3 years, with some as long as 8 years. However, most coffee experts agree that a green coffee peaks in flavor and freshness within one year of harvest, because over-aged coffee beans will lose much of their essential oil content. DecaffeinationDecaffeination is the process of extracting caffeine from green coffee beans prior to roasting. The most common decaffeination process used in the United States is supercritical carbon dioxide (CO2) extraction. In this process, moistened green coffee beans are contacted with large quantities of supercritical CO2 (CO2 maintained at a pressure of about 4,000 pounds force per square inch (28 MPa) and temperatures between 90 and 100 °C [194 and 212 °F]), which removes about 97 % of the caffeine from the beans. The caffeine is then recovered from the CO2, typically using an activated carbon adsorption system. Another commonly used method is solvent extraction, typically using oil (extracted from roasted coffee) or ethyl acetate as a solvent. In this process, solvent is added to moistened green coffee beans to extract most of the caffeine from the beans. After the beans are removed from the solvent, they are steam-stripped to remove any residual solvent. The caffeine is then recovered from the solvent, and the solvent is re-used. Water extraction is also used for decaffeination. Decaffeinated coffeebeans have a residual caffeine content of about 0.1 % on a dry basis. Not all facilities have decaffeination operations, and decaffeinated green coffee beans are purchased by many facilities that produce decaffeinated coffee RoastingAlthough not considered part of the processing pipeline proper, nearly all coffee sold to consumers throughout the world is sold as roasted coffee. This article is licensed under the GNU Free Document LicenseIt uses material from Wikipedia. |